Mechanical smoke ventilation systems (MSVS) are critical to modern fire safety, particularly in complex, high-rise, or subterranean buildings. By using powered extraction to remove smoke, these systems maintain tenable conditions for evacuation and support firefighter access during emergencies.

This guide outlines the design principles and maintenance best practices that ensure effective and compliant mechanical smoke control, with a focus on supporting M&E consultants and procurement teams.

What is a Mechanical

Smoke Ventilation System?

Unlike natural systems that rely on pressure differentials or wind, a mechanical smoke ventilation system uses powered fans to actively extract smoke from a building. These systems are typically composed of:

- Mechanical smoke shafts: Vertical ducts to channel smoke upward

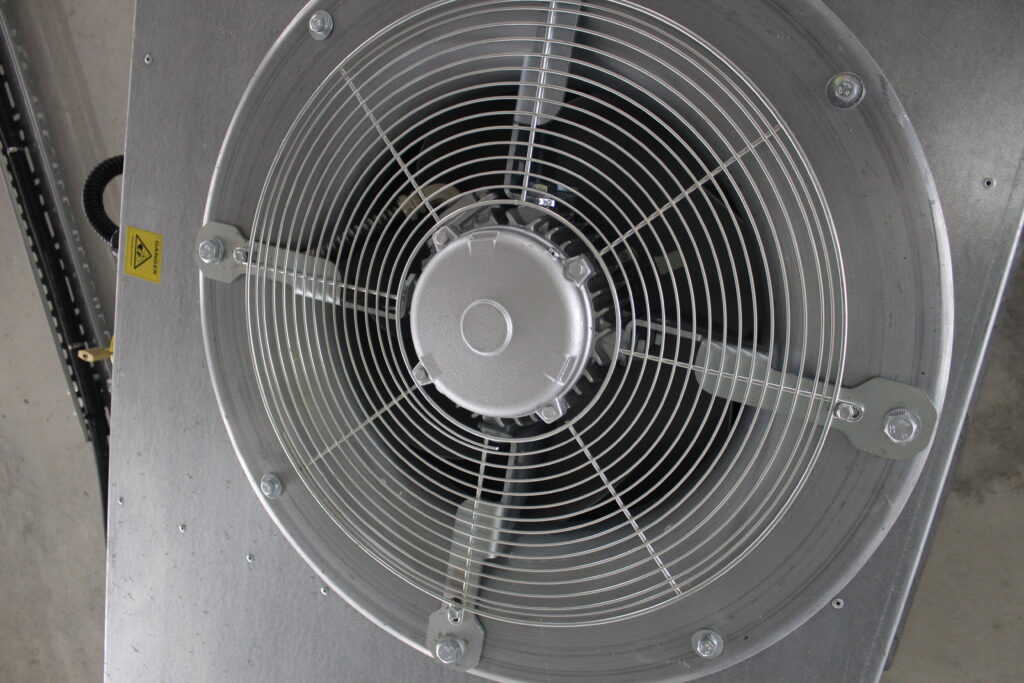

- Smoke extraction fans: High-capacity units for forced removal

- Inlet air paths: Ensuring make-up air flow to sustain extraction

- Fire-rated dampers and grilles

- Smoke control panels: Monitoring and actuation during an incident

Power supply and backup systems: Ensuring operation even in failure scenarios

Where Are They Used?

Mechanical systems are often used when: Extended corridors / dead-end travel distances: When common corridors are long, MSVS is often the right choice.

Published guidance caps dead-end travel distance at ~30 m when the corridor is protected by a suitable mechanical shaft system (measured from the stair).

By contrast, natural solutions are typically used where dead-end distances are short—~7.5 m (up to ~15 m with sprinklers)

Limited façade/roof openings: Deep plans, internal corridors, basements or atria where natural (AOV/NSHEV) can’t achieve the free area or aerodynamic performance needed.

Predictability is critical: Sites exposed to adverse wind/stack effects where natural systems would be unreliable; MSVS gives controlled, repeatable extract rates.

Long/complex escape routes: Extended or convoluted corridors where you need zoned extract to keep escape paths tenable and aid firefighter access.

Tight shafts/retrofit constraints: When existing shaft sizes are small, MSVS (fans + dampers) can often deliver the required performance with smaller ducts/shafts than natural systems.

Basements & enclosed car parks: No viable natural path for smoke/heat—mechanical extract is typically required.

Zoning & containment: You need floor-by-floor or zone control (dampers, smoke shafts) to prevent smoke migration beyond the fire floor.

Dual-use needs: Where the design calls for day-to-day environmental corridor ventilation (with correct cause-and-effect so life-safety takes priority during fire).

Common applications include:

- Residential high-rises

- Commercial towers

- Underground car parks

- Mixed-use developments with atria or long corridors

MSVS Design Considerations

Compliance with Regulations

Design must comply with:

- BS EN 12101-6 for smoke shaft systems

- Approved Document B

- BS 9991 (residential) or BS 9999 (commercial)

Early engagement with fire consultants is essential to align with fire strategy documentation.

System Sizing

Factors to consider:

- Compartment volumes

- Predicted fire loads

- Evacuation times

- Airflow rate targets (typically ≥2.5 m³/s for corridors)

Ducting and

Shaft Layout

- Shafts must be fire-rated and pressure-resistant

- Ducts must minimize bends and avoid pressure drops

Fan and Motor

Selection

- Dual fans are recommended for redundancy

- Motors must operate at high temperatures (e.g. 300°C for 60 mins)

Maintenance Requirements

Mechanical systems must be serviced regularly to ensure reliability. FDS Contracting follows a robust maintenance schedule aligned with BS 7346 and BS EN 12101-6.

These include:

- Monthly visual checks of dampers and panels

- Quarterly tests of fan performance and controls

- Annual full-system smoke tests

- Documentation of all works for audit and compliance

Failing to maintain a mechanical system can result in:

- Legal non-compliance

- System failure during emergency

- Loss of insurance validity

FDS Contracting’s Approach

We offer end-to-end support including:

- Full design and CFD validation

- Installation to LPCB/BRE certification standards

- Planned Preventative Maintenance (PPM) through our sister company FDS Maintenance

- 24/7 emergency call-outs through FDS Maintenance